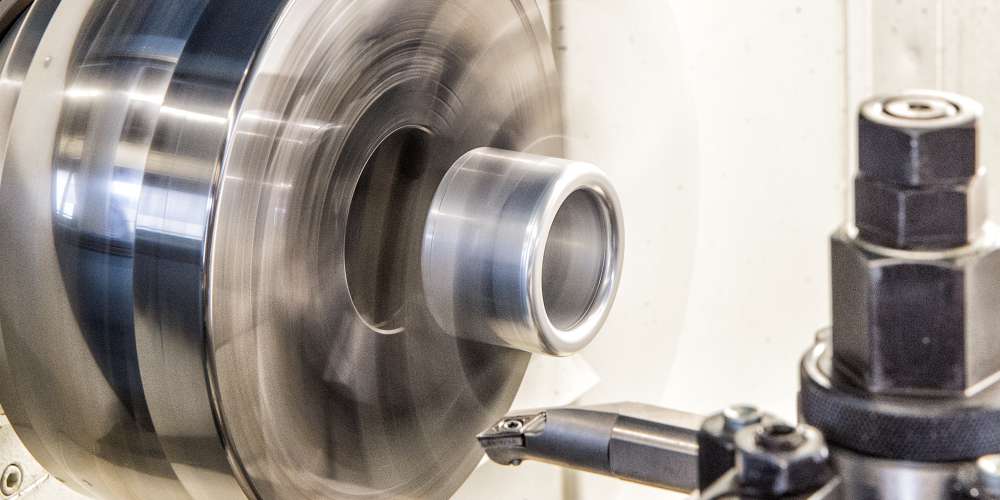

Cold extrusion technology is one of the massive forming processes. The material is made to flow abruptly in a press under high pressure. A press ram presses the raw workpiece into a shaping die. After the pressure has gone, the plastically deformed component is ejected from the press. It has a surface with very good roughness values and highly dimensional precision.

Where cold extrusion makes sense

Basically wherever aluminum is processed, cold extrusion technology has advantages. Typical features where cold extrusion technology works well:

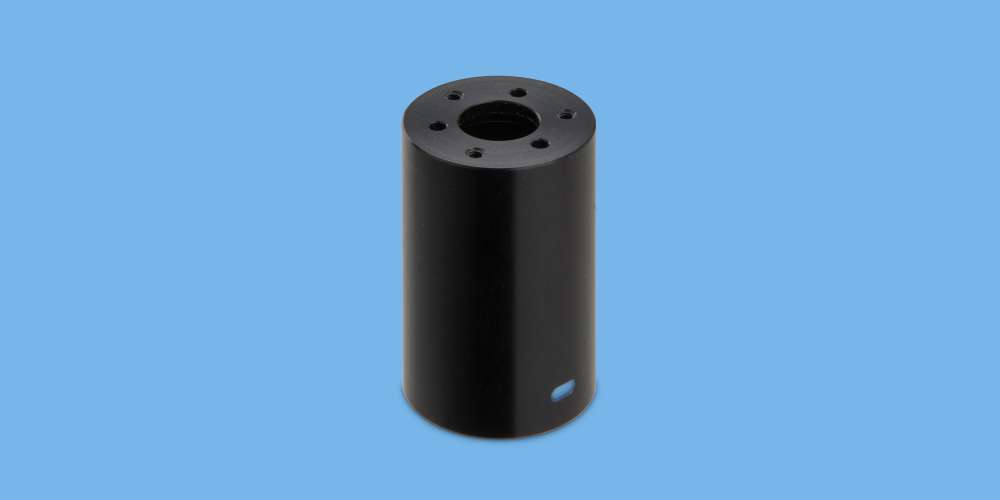

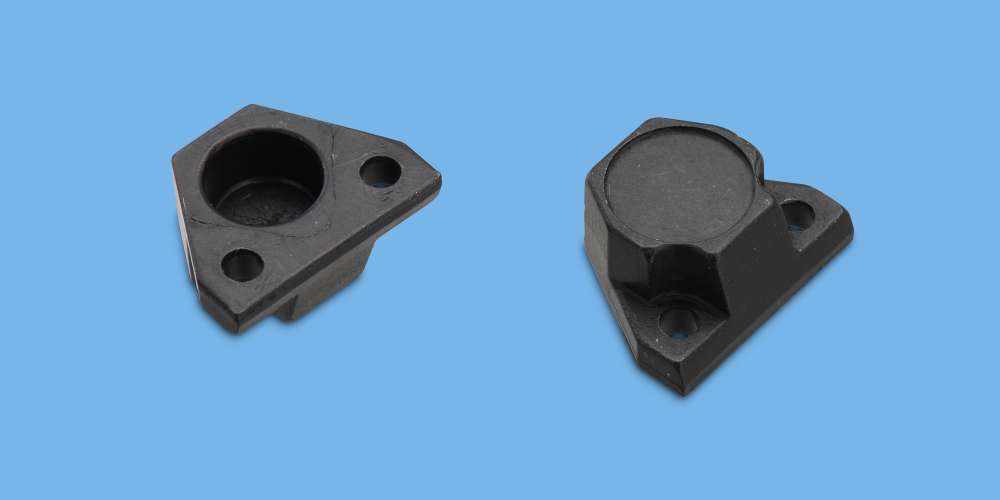

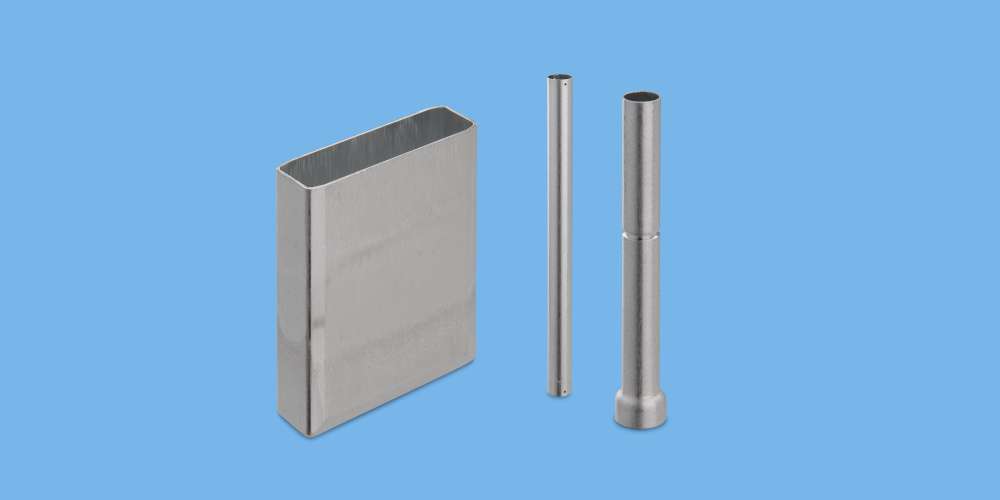

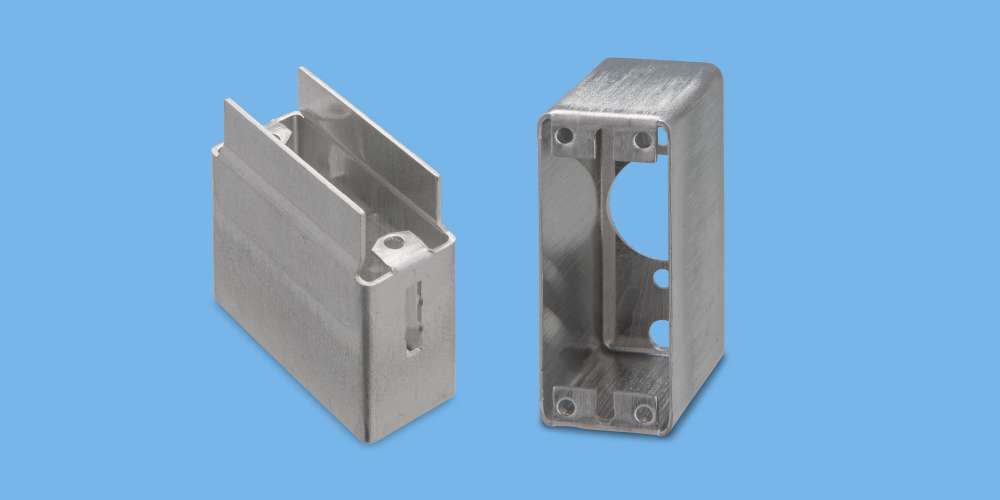

- Hollow parts of any kind

- Forging geometries

- Component contours that cannot be produced by CNC technology, or only at great expense

- Parts with strict requirements on tightness, shielding, or design

What you should pay attention to

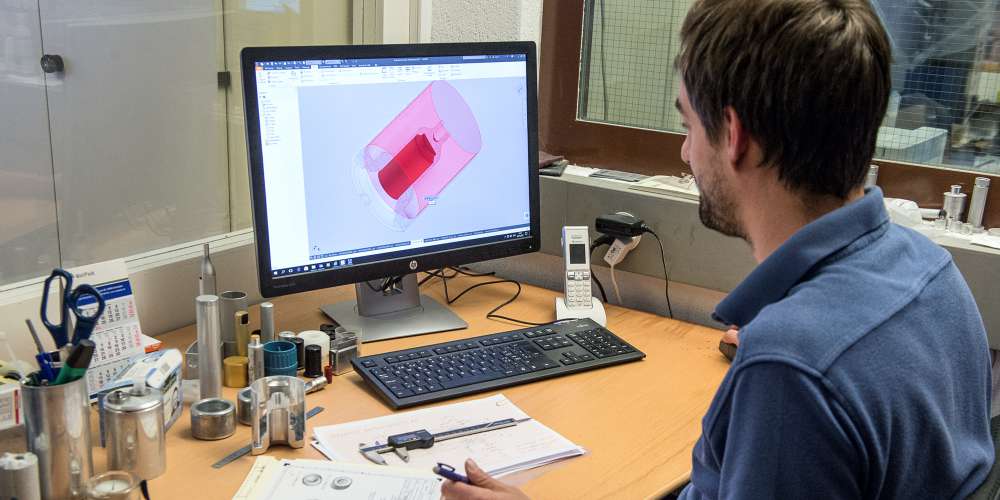

Contact us as soon as possible if you want to develop a new component. Then you can save the most money!